Denali Aire Window Air Conditioner Manual: A Comprehensive Guide

Welcome! This comprehensive guide provides everything you need to know about your Denali Aire window air conditioner. From installation and operation to troubleshooting and maintenance, we’ve got you covered. This manual helps maximize the cooling comfort and efficiency of your unit.

Denali Aire window air conditioners are designed to offer efficient and reliable cooling solutions for various room sizes. These units are engineered with user-friendliness and performance in mind, providing comfort during hot weather. Denali Aire offers a range of models, each catering to different cooling needs and room dimensions.

These air conditioners come equipped with features like adjustable temperature controls, multiple fan speeds, and various operating modes such as Auto, Eco, and Sleep, enhancing user convenience and energy efficiency. Furthermore, many models include a remote control, allowing users to adjust settings from anywhere in the room.

Denali Aire prioritizes both functionality and aesthetics, with sleek designs that seamlessly integrate into any living space. The inclusion of washable air filters ensures clean and healthy air circulation, while the intuitive controls and LED displays make operation straightforward. Denali Aire window air conditioners aim to deliver cooling comfort and convenience.

Overview of Available Denali Aire Models

Denali Aire offers a diverse selection of window air conditioner models, each designed to cater to different room sizes and cooling requirements. Models range from 5,000 BTU units, ideal for smaller spaces up to 250 square feet, to powerful 23,700 BTU units capable of cooling larger areas up to 1,500 square feet.

Popular models include the 6,000 BTU unit, perfect for spaces around 250 square feet, the 8,000 BTU unit for rooms up to 350 square feet, and the 10,000 BTU unit suitable for areas up to 450 square feet. For larger spaces, the 12,000 BTU and 14,000 BTU models are available, cooling spaces up to 550 and 700 square feet, respectively.

Some models also come with additional features like electric heaters, providing both cooling and heating capabilities. Denali Aire models are designed with user-friendly controls, energy-efficient operation, and sleek aesthetics. Each model includes a detailed user manual to guide installation, operation, and maintenance.

Key Features and Technologies

Denali Aire window air conditioners are equipped with a range of features and technologies designed to enhance cooling performance and user experience. Many models incorporate adjustable four-way air direction control, enabling precise airflow management and even distribution of cool air throughout the room. Electronic controls with LED displays offer intuitive operation and temperature adjustment, ranging from 64°F to 86°F.

Select models include convenient auto, sleep, and eco modes, optimizing energy consumption while maintaining comfort. The eco mode automatically adjusts cooling output based on room temperature, while the sleep mode gradually increases the temperature overnight for enhanced sleep comfort. A full-function remote control allows users to conveniently control the air conditioner from anywhere in the room.

Furthermore, Denali Aire units feature washable air filters that require no replacement, ensuring clean and healthy air circulation. Some models also include electric heaters for year-round comfort. These features combine to provide efficient, convenient, and reliable cooling solutions for various room sizes and user preferences.

Understanding BTU and Room Size Compatibility

BTU, or British Thermal Units, is a critical measurement when selecting a window air conditioner. It indicates the amount of heat the unit can remove from a room per hour. Choosing the right BTU rating for your room size is essential for optimal cooling efficiency and comfort. An undersized unit will struggle to cool the space effectively, while an oversized unit may cycle on and off frequently, leading to energy waste and inconsistent temperatures.

Denali Aire offers a variety of models with different BTU ratings to suit various room sizes. For example, a 6,000 BTU unit is ideal for spaces up to 250 square feet, while an 8,000 BTU unit can cool up to 350 square feet. Larger rooms, up to 550 square feet, may require a 12,000 BTU unit, and very large spaces up to 1,500 square feet might need a 23,700 BTU model.

Consult the product specifications and the guidelines in this manual to determine the appropriate BTU rating for your specific room size. Proper BTU selection ensures efficient cooling and a comfortable indoor environment.

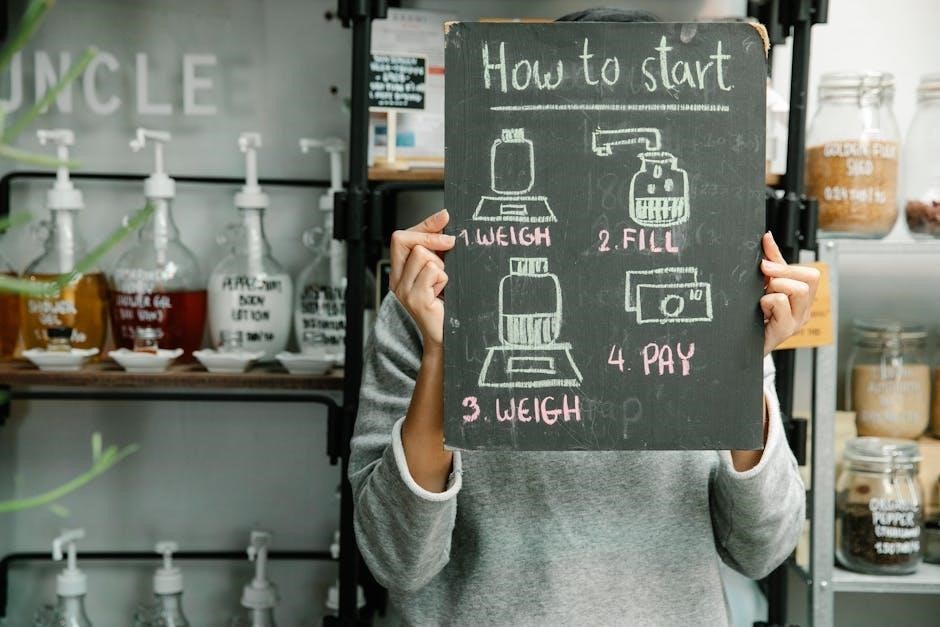

Operating Modes: Auto, Eco, Sleep

Denali Aire window air conditioners come equipped with several operating modes designed to enhance your comfort and energy savings. Understanding these modes can help you optimize your cooling experience.

Auto Mode: In auto mode, the air conditioner automatically adjusts the fan speed and temperature based on the room’s current temperature. The unit’s sensors detect the temperature and select the appropriate settings to maintain a consistent and comfortable environment. This mode provides a hands-free cooling solution.

Eco Mode: Eco mode is designed to minimize energy consumption. When activated, the air conditioner cycles on and off, only operating when necessary to maintain the desired temperature. This mode helps reduce electricity bills while still providing adequate cooling. It’s a smart choice for environmentally conscious users.

Sleep Mode: Sleep mode is tailored for nighttime use. It gradually increases the temperature over time, creating a more comfortable sleeping environment. This prevents the room from becoming too cold during the night and helps conserve energy. The display lights may dim or turn off in sleep mode for undisturbed rest.

Remote Control Functionality

The Denali Aire window air conditioner remote control provides convenient access to all the unit’s features from anywhere in the room. It is essential for easy operation and control of your comfort settings. Understanding the remote’s functions can greatly enhance your user experience.

The remote allows you to adjust the temperature, fan speed, and operating mode. Dedicated buttons are typically available for each function, making it simple to switch between auto, eco, sleep, and other modes. You can also use the remote to turn the air conditioner on or off and set a timer for automatic operation.

Many Denali Aire remotes also include a display screen that shows the current temperature setting, operating mode, and timer status. This allows you to easily monitor and adjust the settings without having to be near the unit. The remote’s intuitive design ensures that you can quickly and easily customize your cooling experience to your preferences.

Some remotes may also have additional features such as a “follow me” function, where the remote acts as a thermostat, ensuring that the temperature is precisely controlled where you are located in the room.

Installation Guide

Proper installation is crucial for optimal performance and safety of your Denali Aire window air conditioner. This guide provides step-by-step instructions to ensure a secure and efficient setup. Before you begin, carefully review the safety precautions outlined in the manual.

First, select a suitable window that fits the dimensions specified for your model. Ensure the window can support the weight of the unit and that there is access to a grounded electrical outlet. Prepare the window opening by cleaning the sill and frame;

Next, attach the included mounting brackets to the air conditioner. Follow the instructions carefully to ensure they are properly secured. Position the air conditioner in the window opening, making sure it is level and stable. Extend the side panels to fill the remaining space and create a tight seal.

Secure the unit using the provided hardware, such as screws or locking mechanisms. Install the window support bracket if included, to provide additional stability. Finally, plug the air conditioner into the grounded outlet. Test the unit to ensure it is functioning correctly. Refer to online videos for visual aids.

Cleaning and Maintenance

Regular cleaning and maintenance are essential to keep your Denali Aire window air conditioner running efficiently and prolong its lifespan. A clean unit cools better and uses less energy. Before cleaning, always disconnect the power cord from the outlet to prevent electrical shock.

The most important maintenance task is cleaning the air filter. At least once a month, remove the filter and wash it with warm water and mild soap. Rinse thoroughly and allow it to air dry completely before reinstalling. A dirty filter restricts airflow, reducing cooling performance and increasing energy consumption.

Periodically clean the exterior of the unit with a damp cloth and mild detergent. Avoid using harsh chemicals or abrasive cleaners, as they can damage the finish. Gently wipe the front panel and cabinet to remove dust and dirt. Ensure the unit is completely dry before plugging it back in.

At the end of the cooling season, thoroughly clean the air conditioner before storing it. Remove the filter, clean the exterior, and inspect the unit for any damage. Store it in a cool, dry place, covered with a protective cover.

Troubleshooting Common Issues

Even with proper care, you might encounter some common issues with your Denali Aire window air conditioner. Before contacting customer support, try these troubleshooting steps. If the unit doesn’t turn on, check the power cord, the outlet, and the circuit breaker. Ensure the air conditioner is properly plugged in and the outlet is working.

If the air conditioner is not cooling effectively, clean the air filter. A dirty filter restricts airflow and reduces cooling capacity. Also, check that the temperature setting is appropriate and that the unit is not in fan-only mode.

If the air conditioner is making unusual noises, check for any loose parts or obstructions. Sometimes, debris can get caught in the fan blades. If you hear a rattling sound, ensure the unit is securely mounted in the window.

If water is leaking from the unit, check the drain plug. Make sure it is properly installed and not clogged. If the problem persists, consult a qualified technician.

If the remote control is not working, replace the batteries. Ensure there are no obstructions between the remote and the unit. If these steps don’t resolve the issue, refer to the user manual for further assistance.

Safety Precautions

Your safety is paramount when operating your Denali Aire window air conditioner. Always disconnect the power before cleaning or performing maintenance. Never use an extension cord with this unit to avoid fire hazards. Ensure the air conditioner is properly grounded.

Do not insert fingers or objects into the air outlet. This could cause injury or damage to the unit. Keep flammable materials away from the air conditioner. Never spray water or cleaning products directly onto the unit’s electrical components.

If you notice any unusual smells, sounds, or smoke, immediately turn off the unit and disconnect it from the power source. Contact a qualified technician for inspection and repairs. Do not attempt to repair the unit yourself.

Ensure the air conditioner is securely installed in the window to prevent it from falling. Follow the installation instructions carefully. Regularly inspect the power cord for any signs of damage. Replace it if necessary.

Keep children and pets away from the unit to prevent accidental injury. Supervise children when the air conditioner is in use. These precautions will help ensure safe and reliable operation of your Denali Aire window air conditioner.

Warranty Information and Support

Your Denali Aire window air conditioner comes with a limited warranty, safeguarding against manufacturing defects in materials and workmanship. The specific warranty period is detailed in the warranty card included with your unit. Please retain your purchase receipt as proof of purchase, as it is required for warranty claims.

This warranty covers repair or replacement of defective parts. It does not cover damage caused by misuse, improper installation, neglect, or unauthorized repairs. To initiate a warranty claim, contact Denali Aire customer support via phone or email. Our contact information is available on our website and in the user manual.

Before contacting support, please have your model number, serial number, and purchase date readily available. Our support team will guide you through the troubleshooting process and determine if warranty service is necessary. For out-of-warranty repairs, we can provide a list of authorized service centers in your area.

We also offer comprehensive online support resources, including FAQs, troubleshooting guides, and instructional videos, on the Denali Aire website. Our goal is to ensure your complete satisfaction with your Denali Aire product.